La pompe à fût chimique HD, également appelée pompe de transfert de fûts de pétrole, est conçue pour offrir des performances stables, une utilisation conviviale et une qualité fiable à un prix compétitif. Tous les composants critiques sont importés, notamment les roulements à billes à gorge profonde, les joints en caoutchouc fluoré VT, les joints d'huile en fluoropolymère TFEP et les chemises d'arbre provenant de Suisse, du Japon et de Taïwan. Cela garantit des matériaux authentiques et une durabilité structurelle, offrant aux clients une fiabilité élevée et constante ainsi qu'une longue durée de vie.

Débit maximum :

Maximum 198 L/minTête maximale :

Maximum 30 mTempérature :

Speed: 0-12,000 r/minMatériel :

304, 316L, PVDF, PP, Aluminum Alloy, Hastelloy, Plastic, HastelloyLa pompe à fûts chimiques HD est spécialement conçue pour un fonctionnement sûr et efficace, ce qui la rend idéale pour le transfert de divers produits chimiques corrosifs, huiles et solvants depuis des fûts et des conteneurs. Sa construction robuste est dotée de passages de fluides en PTFE et en caoutchouc fluoré résistants aux produits chimiques. Conçue pour la sécurité de l'opérateur, elle intègre une conception étanche et des mécanismes de fonctionnement sans étincelles, ce qui la rend adaptée aux environnements volatiles. Que ce soit pour la fabrication industrielle, les laboratoires ou la gestion des déchets, la pompe à fûts chimiques HD offre une solution fiable et économique pour une gestion sûre des fluides.

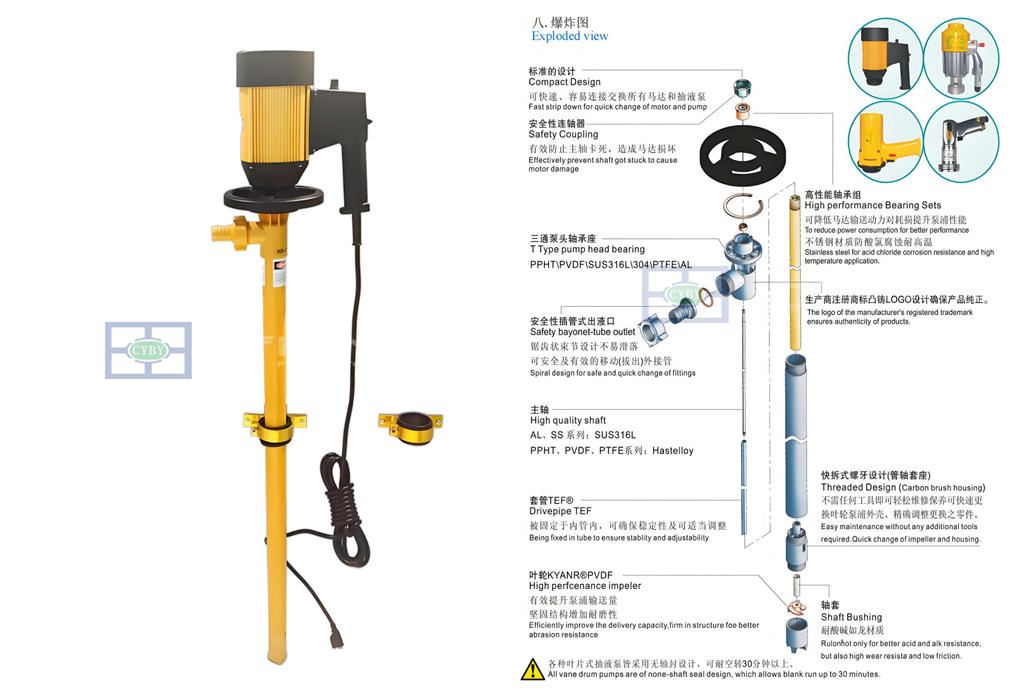

La pompe à fût chimique est composée de composants essentiels tels que le tube de pompe, le moteur/la tête d'entraînement pneumatique, la turbine, l'orifice de refoulement et le joint d'étanchéité, qui assurent ensemble un transport sûr et efficace des liquides chimiques. Voici un aperçu des caractéristiques de chaque composant :

Pour des recommandations spécifiques en matière de matériaux ou de conception adaptées à votre application, veuillez contacter notre équipe d'assistance technique.

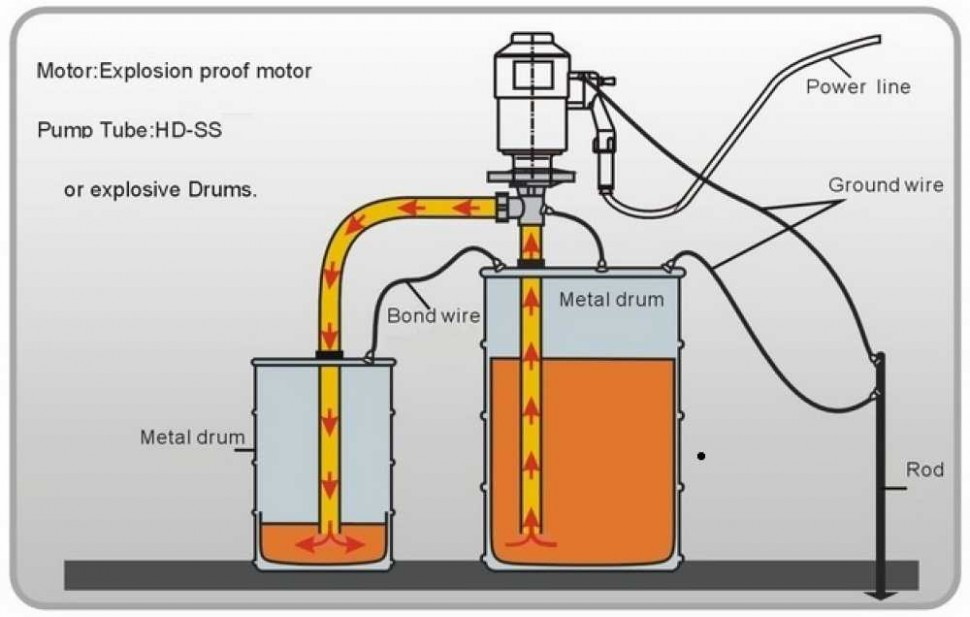

La pompe à fût chimique est entraînée par un moteur électrique ou pneumatique, qui entraîne la turbine à l'intérieur de la pompe à grande vitesse. La force centrifuge est utilisée pour aspirer l'huile du fond du récipient vers le tuyau de la pompe, où elle est accélérée par la turbine. L'énergie cinétique du liquide est convertie en pression stable dans la chambre de la pompe, puis évacuée par la sortie, assurant un transport efficace. L'ensemble du système utilise une conception sans joint, éliminant le risque de fuite et garantissant un transfert sûr, propre et économique de l'huile et des fluides visqueux (tels que l'huile de lubrification, le carburant, etc.). Prenons l'exemple d'une pompe à fût pour huile :

Conception complète et étanche

Il est doté d'une conception sans arbre et d'une structure de tube de pompe sans fuite pour éliminer les risques de fuite, ce qui le rend particulièrement adapté au transport de liquides corrosifs, inflammables, explosifs et de haute pureté, garantissant la sécurité opérationnelle.

Plusieurs matériaux et modèles disponibles

Offre une variété de matériaux pour tubes de pompe, notamment le polypropylène, le PVDF, le PTFE, l'acier inoxydable et l'alliage d'aluminium, afin de répondre aux exigences de compatibilité de l'industrie chimique. Adapté aux liquides de faible, moyenne et haute viscosité, il est largement utilisé dans plus de 80 % des applications industrielles.

Très efficace et léger, facile à utiliser

L'ensemble est léger et très maniable, permettant de vider rapidement un fût standard de 200 litres en 2 à 3 minutes. Doté d'interfaces de connexion rapide et d'une structure modulaire, le montage et le démontage s'effectuent sans outils, améliorant considérablement la maintenance et l'efficacité opérationnelle.

Prend en charge plusieurs options d'entraînement électrique

Disponible avec des options d'entraînement électrique (avec contrôle de vitesse et protection contre les surcharges) ou pneumatique, s'adaptant à différentes conditions d'alimentation sur site et offrant des solutions de configuration d'équipement plus flexibles.

Conception de compatibilité

Conception d'interface standard compatible avec divers tuyaux et connecteurs ; les raccords améliorés ne nécessitent aucun alignement et peuvent être rapidement connectés, adaptés à une large gamme de fluides allant des milieux ordinaires aux acides et alcalis forts.

Fiabilité et facilité d'entretien

Chaque pompe est soumise à des tests rigoureux en usine et supporte un fonctionnement à sec de courte durée sans dommage. Sa structure modulaire simplifie l'entretien et le démontage, le démontage et le remontage s'effectuant en 10 minutes seulement. Une large gamme d'accessoires est également disponible pour répondre à divers besoins.

La pompe chimique à tambour est principalement utilisée dans les industries et scénarios suivants :

Changyu Pumps est un fabricant et fournisseur de pompes pour fûts chimiques. Nous proposons des solutions de pompes pour fûts chimiques adaptées à différents contenants. Qu'il s'agisse de réservoirs standards, de fûts industriels, de conteneurs IBC ou de conteneurs spéciaux non standards, la profondeur d'immersion influence directement les performances de pompage et la sécurité opérationnelle. Les exigences d'immersion courantes incluent 500 mm, 700 mm, 1 000 mm et 1 200 mm, avec une sélection de tubes de pompe standard, offrant une grande adaptabilité et une disponibilité immédiate.

Pour les conteneurs de profondeur spéciale ou non standard, tels que les réservoirs de stockage à fond profond, les corps de réservoir personnalisés ou les structures de bassin de pompage, Changyu propose des solutions de tubes de pompage sur mesure, d'une longueur allant de 300 mm à plus de 3 mètres, parfaitement adaptées à vos conditions d'exploitation et à vos besoins en équipements. Pour plus d'informations sur les sélections standard ou les solutions personnalisées, n'hésitez pas à contacter notre équipe technique afin d'obtenir des solutions de pompage sur mesure et des informations détaillées sur les produits.

Si vous avez besoin de plus d'informations sur des applications spécifiques ou sur la sélection de produits, n'hésitez pas à consulter notre équipe technique professionnelle.

Nos horaires

Lundi 21/11 - Mer 23/11 : 9h - 20h

Jeu. 24/11 : fermé - Joyeux Thanksgiving !

Vendredi 25/11 : 8h00 - 22h00

Sam 26/11 - Dim 27/11 : 10h - 21h

(toutes les heures sont l'heure de l'Est)