Cet article analyse les types de pompes disponibles pour des supports spécifiques afin de vous aider à faire une sélection plus rapide et plus efficace, et fournit également des données pour votre référence.

1.Analyse des caractéristiques des conditions de travail

Caractéristiques moyennes

Forte acidité : pH = 2 est un environnement acide fort, et la résistance à la corrosion acide du matériau doit être prise en compte

Oxydation : Le milieu a des propriétés oxydantes et la capacité antioxydante du matériau doit être évaluée

Contenant des particules solides : La présence de petites particules de sable entraînera des problèmes d'usure (il est recommandé de confirmer la distribution granulométrique et la concentration)

2.Sélection des matériaux

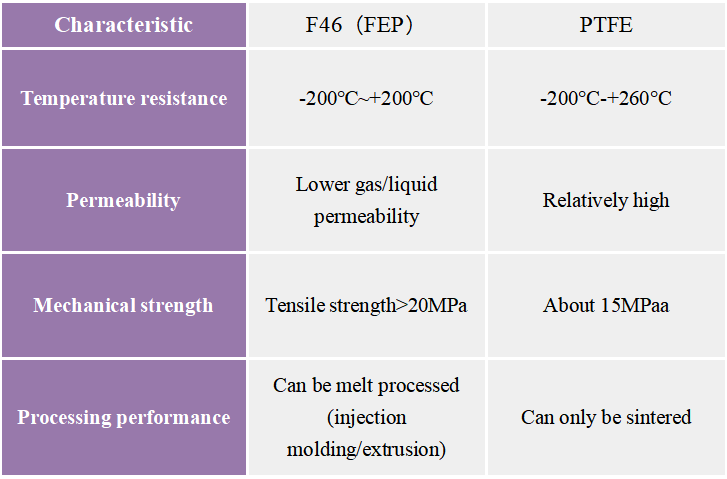

2.1 Il est recommandé d'utiliser un corps de pompe revêtu de PTFE (polytétrafluoroéthylène) ou de F46, qui présente les caractéristiques suivantes :

✓ Forte résistance aux acides (applicable à toute la gamme de pH 0-14)

✓ Excellente résistance à l'oxydation

✓ Surface lisse et difficile à écailler

2.2 joints mécaniques il est recommandé d'utiliser le couple SiC/SiC, qui est plus résistant à l'usure des particules que le graphite

2.3 Paramètres de sélection des clés

Notes requises Vitesse ≤ 2900 tr/min : réduit l'érosion et l'usure des particules

Type de roue semi-ouverte/roue ouverte : évite le blocage du canal d'écoulement de la roue fermée

La conception de l'espace est de 0,3 à 0,5 mm plus grande que celle de la pompe standard pour permettre le passage des particules

Type de joint d'arbre : garniture mécanique double extrémité + eau de rinçage (la solution de rinçage externe Plan53B est recommandée)

3. Points de conception spéciaux

Structure résistante à l'usure

Le couvercle avant de la turbine est épaissi de 2 à 3 mm

Une plaque résistante à l'usure remplaçable est placée sur la volute du corps de la pompe

La surface des pièces traversantes peut être durcie

4. Suggestions d'opérations

Il est recommandé d'installer un filtre de type Y à l'entrée (la taille des mailles est déterminée par la taille des particules)

Le débit minimum doit être > 30 % Qn pour éviter les dépôts solides

Le canal d'écoulement doit être rincé à temps lorsque la machine est arrêtée

5. Modèles typiques recommandés

Domestique : Pompe centrifuge en fluoroplastique IHF80-65-160 (avec kit de modification résistant à l'usure)

Importé : CPK80-200F (avec turbine pour supports granulaires)

Si le budget est limité mited, vous pouvez considérer : FSB80-50-200 (besoin de confirmer les paramètres réels des particules)

Si vous avez de meilleures idées, n'hésitez pas à nous laisser un message. Nous serons ravis d'en apprendre davantage et de vous offrir un meilleur service.

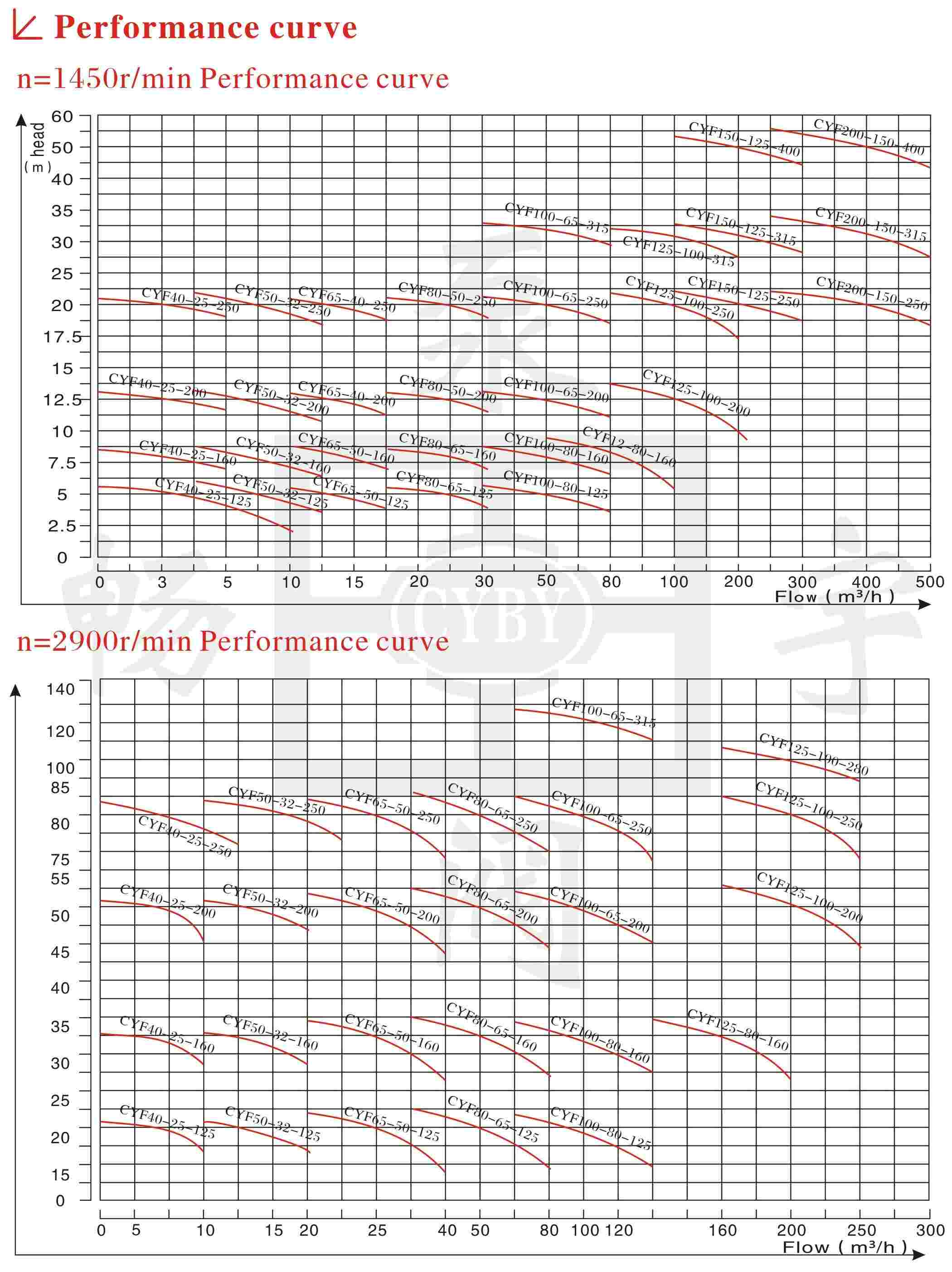

Ci-joint la courbe de performance de notre pompe chimique IHF:

Nos horaires

Lundi 21/11 - Mer 23/11 : 9h - 20h

Jeu. 24/11 : fermé - Joyeux Thanksgiving !

Vendredi 25/11 : 8h00 - 22h00

Sam 26/11 - Dim 27/11 : 10h - 21h

(toutes les heures sont l'heure de l'Est)